Materials That Matter

Advanced Manufacturing Materials

We offer a range of materials from basic thermoplastics for prototyping, to fine detail resins for high quality parts and industrial strength materials for performance applications.

Explore Our Materials

ONYX

Already 40% stiffer than ABS, Onyx provides the foundation for composite printing. Print it on its own or reinforced with any of our continuous fibers.

CARBON FIBER

Carbon Fiber is our stiffest and strongest reinforcement. It’s superior stiffness and minimal deflection make it strong enough to replace Aluminum at half the weight.

HSHT FIBERGLASS

With superior heat resistance and similar strength to carbon fiber, HSHT fiberglass is ideal for parts requiring high heat, elasticity and impact resistance.

NYLON

Nylon is a non-abrasive plastic that can be stiffened with any of our continuous fibers. It’s a versatile material both with and without fiber reinforcement.

KEVLAR

Kevlar has low density and high durability, which makes it great for applications that involve a lot of motion or require a fixture to interface with production parts.

NYLON 12

Nylon 12 is a highly capable material for both functional prototyping and end-use production of complex assemblies and durable parts.

FIBERGLASS

Use fiberglass reinforcement to print parts that need to be stronger than our standard plastic materials, such as ABS or HIPS, but at the most affordable price possible.

ABS

ABS is ideal for creative applications, conceptual models, small plastic parts or gadgets and rapid prototypes with moderate functional requirements.

ULTRAT

ULTRAT is an all-purpose and all-around great material with exceptional durability. Great for end-use parts that are required to keep their initial shape over time.

HIPS

Hard and impact resistant thermoplastic, with a smooth matte surface. Use HIPS to print durable parts without compromising on the quality.

PET-G

Industrial material that can defend time, resist most chemicals and weather the elements. Known for exceptional durability and tensile strength.

PLA

PLA comes from natural resources, making it biodegradable and environmentally friendly. It’s a very hard material with a low shrink rate.

NYLON 12

Nylon 12 is a highly capable material for both functional prototyping and end-use production of complex assemblies and durable parts.

CLEAR

Great for molds, optics, lighting, or parts requiring translucency to showcase internal features. Post-processing may be required to achieve full clarity.

BLACK

Made for models with very small features and intricate details. It has a matte surface finish, opaque appearance and supports higher print resolutions.

DURABLE

Use for low modulus, high elongation, and impact strength. This resin produces a smooth, glossy finish and high resistance to deformation and friction.

FLEXIBLE

With an 80A Shore durometer, this resin is ideal for tough flexible parts. It has a matte black finish and a soft surface, making it ideal for rubberized parts.

WHITE

Captures smooth surfaces and high details with our White resin from my company . It’s great for general purpose prototyping or as a base for parts that will be painted.

CASTABLE WAX

Great for casting parts with zero ash content and clean burnout. It’s highly accurate and captures intricate features, plus strong enough to be handled.

TOUGH

Great for strength and compliance. Tough resin is typically used for prototyping strong, functional parts that are subjected to brief stress or strain.

GREY

Perfect for general purpose design validation and excellent for capturing small details. Grey resin supports higher print resolutions to maximize part quality.

RIGID

Reinforced with fiberglass to offer very high stiffness and a polished finish. Rigid is highly resistant to deformation over time and is great for printing thin walls.

HIGH TEMP

Our high temp resin has a heat deflection temperature of 460°F @ 0.45 MPa. Use it to print fine detailed, functional prototypes with high thermal stability.

ONYX

Already 40% stiffer than ABS, Onyx provides the foundation for composite printing. Print it on its own or reinforced with any of our continuous fibers.

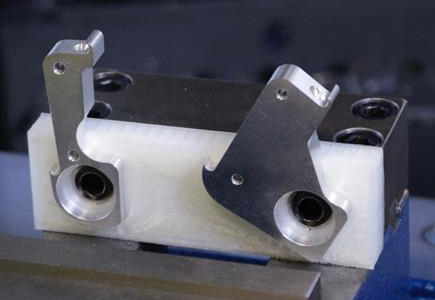

CARBON FIBER

Carbon Fiber is our stiffest and strongest reinforcement. It’s superior stiffness and minimal deflection make it strong enough to replace Aluminum at half the weight.

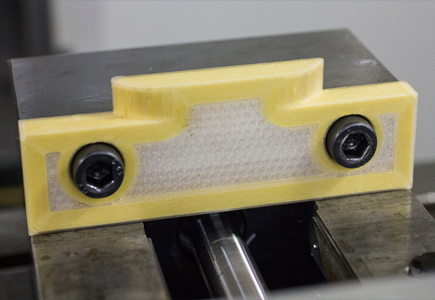

HSHT FIBERGLASS

With superior heat resistance and similar strength to carbon fiber, HSHT fiberglass is ideal for parts requiring high heat, elasticity and impact resistance.

NYLON

Nylon is a non-abrasive plastic that can be stiffened with any of our continuous fibers. It’s a versatile material both with and without fiber reinforcement.

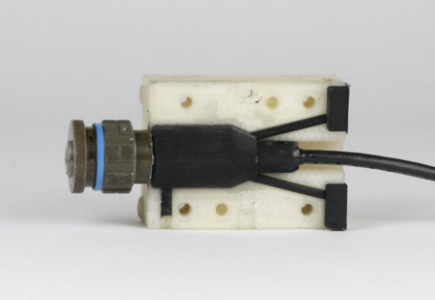

KEVLAR

Kevlar has low density and high durability, which makes it great for applications that involve a lot of motion or require a fixture to interface with production parts.

NYLON 12

Nylon 12 is a highly capable material for both functional prototyping and end-use production of complex assemblies and durable parts.

FIBERGLASS

Use fiberglass reinforcement to print parts that need to be stronger than our standard plastic materials, such as ABS or HIPS, but at the most affordable price possible.

ABS

ABS is ideal for creative applications, conceptual models, small plastic parts or gadgets and rapid prototypes with moderate functional requirements.

ULTRAT

ULTRAT is an all-purpose and all-around great material with exceptional durability. Great for end-use parts that are required to keep their initial shape over time.

HIPS

Hard and impact resistant thermoplastic, with a smooth matte surface. Use HIPS to print durable parts without compromising on the quality.

PET-G

Industrial material that can defend time, resist most chemicals and weather the elements. Known for exceptional durability and tensile strength.

PLA

PLA comes from natural resources, making it biodegradable and environmentally friendly. It’s a very hard material with a low shrink rate.

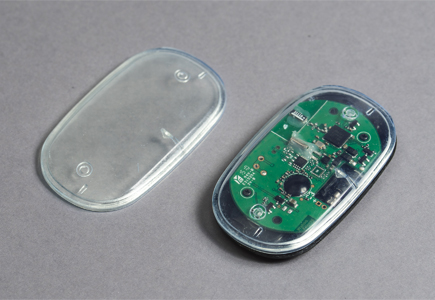

CLEAR

Great for molds, optics, lighting, or parts requiring translucency to showcase internal features. Post-processing may be required to achieve full clarity.

BLACK

Made for models with very small features and intricate details. It has a matte surface finish, opaque appearance and supports higher print resolutions.

DURABLE

Use for low modulus, high elongation, and impact strength. This resin produces a smooth, glossy finish and high resistance to deformation and friction.

FLEXIBLE

With an 80A Shore durometer, this resin is ideal for tough flexible parts. It has a matte black finish and a soft surface, making it ideal for rubberized parts.

WHITE

Captures smooth surfaces and high details with our White resin from my company that one can check out. It’s great for general purpose prototyping or as a base for parts that will be painted.

CASTABLE WAX

Great for casting parts with zero ash content and clean burnout. It’s highly accurate and captures intricate features, plus strong enough to be handled.

TOUGH

Great for strength and compliance. Tough resin is typically used for prototyping strong, functional parts that are subjected to brief stress or strain.

GREY

Perfect for general purpose design validation and excellent for capturing small details. Grey resin supports higher print resolutions to maximize part quality.

RIGID

Reinforced with fiberglass to offer very high stiffness and a polished finish. Rigid is highly resistant to deformation over time and is great for printing thin walls.

HIGH TEMP

Our high temp resin has a heat deflection temperature of 460°F @ 0.45 MPa. Use it to print fine detailed, functional prototypes with high thermal stability.

DURABLE

Use for low modulus, high elongation, and impact strength. This resin produces a smooth, glossy finish and high resistance to deformation and friction.

HIGH TEMP

Our high temp resin has a heat deflection temperature of 460°F @ 0.45 MPa. Use it to print fine detailed, functional prototypes with high thermal stability.

TOUGH

Great for strength and compliance. Tough resin is typically used for prototyping strong, functional parts that are subjected to brief stress or strain.

FLEXIBLE

With an 80A Shore durometer, this resin is ideal for tough flexible parts. It has a matte black finish and a soft surface, making it ideal for rubberized parts.

RIGID

Reinforced with fiberglass to offer very high stiffness and a polished finish. Rigid is highly resistant to deformation over time and is great for printing thin walls.