Additive Technology: SLA

Stereolithography

SLA is capable of printing extremely accurate parts using a wide range of resins. It’s great for fine details and parts that require injection mold like finishes.

Description

SLA technology uses ultraviolet light to cure photopolymer resin layer by layer. It offers a higher resolution than other technologies, allowing you to print parts with fine details and surface finishes.

Strengths

Fine features, with high detail, smooth, injection mold like surfaces and a wide range of materials.

Weaknesses

Support marks may be visible, cured resins can be brittle, not recommended for heavy wear and tear parts.

Standard Resins

White, Grey, Black, Clear and Castable Wax

Engineering Resins

Rigid, Durable, High Temp, Tough and Flexible

Price

$$$$$

Lead Time

3-4 Days

Tolerances

± 0.15 mm

Min Wall Thickness

0.5 mm

Max Build Volume

145 x 145 x 175 mm

( 5.7 x 5.7 x 6.9 in )

Resolutions Available

25 Micron – 0.025 mm

50 Micron – 0.05 mm

100 Micron – 0.1 mm

Advantages of SLA

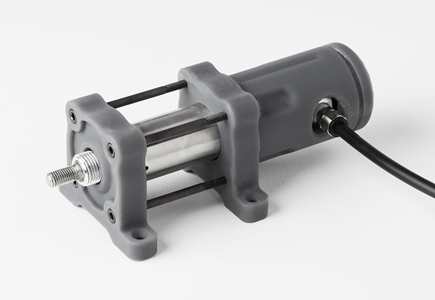

Exceptional Quality Parts

We offer a wide range of materials with stunning surface finishes.

Have questions about Stereolithography?

Our additive specialists can help.

Explore SLA Materials

Below is a list of materials we offer for Stereolithography.

WHITE RESIN

Captures smooth surfaces and high details with our White resin. It’s great for general purpose prototyping or as a base for parts that will be painted.

GREY RESIN

Perfect for general purpose design validation and excellent for capturing small details. Grey resin supports higher print resolutions to maximize part quality.

CASTABLE WAX RESIN

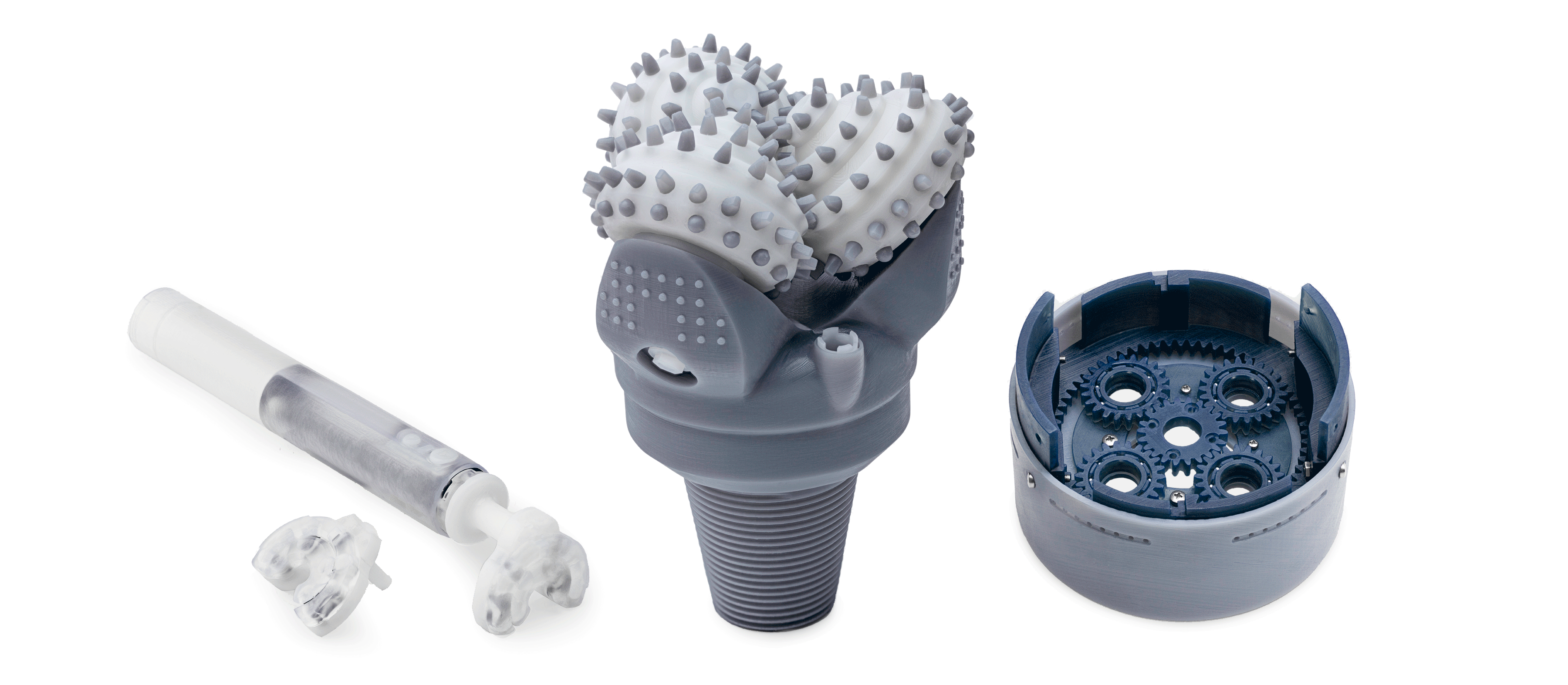

Great for casting parts with zero ash content and clean burnout. It’s highly accurate and captures intricate features, plus strong enough to be handled.

DURABLE RESIN

Use for low modulus, high elongation, and impact strength. This resin produces a smooth, glossy finish and high resistance to deformation and friction.

FLEXIBLE RESIN

With an 80A Shore durometer, this resin is ideal for tough flexible parts. It has a matte black finish and a soft surface, making it ideal for rubberized parts.

BLACK RESIN

Made for models with very small features and intricate details. It has a matte surface finish, opaque appearance and supports higher print resolutions.

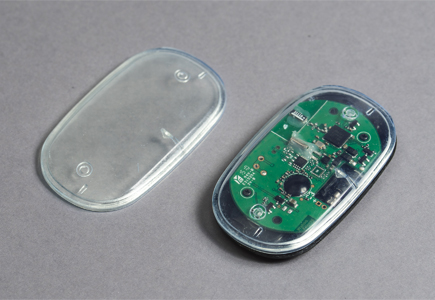

CLEAR RESIN

Great for mold-making, optics, lighting, or parts requiring translucency to showcase internal features. Post-processing may be required to achieve full clarity.

RIGID RESIN

Reinforced with fiberglass to offer very high stiffness and a polished finish. Rigid is highly resistant to deformation over time and is great for printing thin walls.

TOUGH RESIN

Great for strength and compliance. Tough resin is typically used for prototyping strong, functional parts and assemblies that are subjected to brief stress or strain.

HIGH TEMP RESIN

Our high temp resin has a heat deflection temperature of 238 °C @ 0.45 MPa. Use it to print fine detailed, functional prototypes with high thermal stability.