Additive Technology: FFF

Fused Filament Fabrication

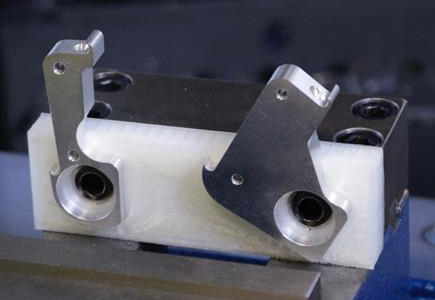

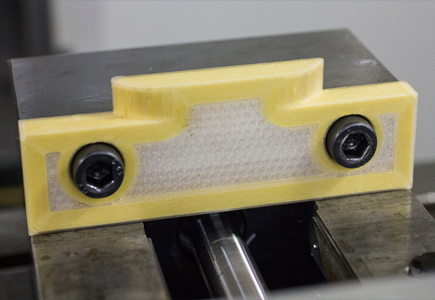

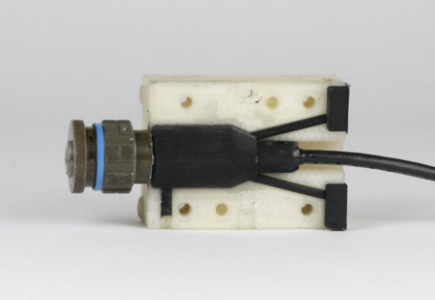

FFF is our most popular print process. It’s mainly used for high strength parts, functional prototypes, manufacturing fixtures and small batch production.

Description

FFF is similar to FDM technology, material is extruded and parts are created layer by layer, but it also allows us to add a continuous fiber reinforcement to the inside of a part.

Strengths

Incredibly strong, composite parts, with high detail, smooth surface finish and dimensionally stable materials.

Weaknesses

Support marks may be visible, limited base materials and colors available.

Base Materials

Onyx or Nylon

Reinforcement

Carbon Fiber, Kevlar, Fiberglass or HSHT Fiberglass

Price

$$$$$

Lead Time

1-2 Days

Tolerances

± 0.5 mm

Min Wall Thickness

0.4 mm

Min Fiber Wall Thickness

1.0 mm

Max Build Volume

330 x 270 x 200 mm

( 12.9 x 10.5 x 7.8 in )

Resolutions Available

50 Micron – 0.05 mm

100 Micron – 0.1 mm

125 Micron – 0.125 mm

200 Micron – 0.2 mm

Advantages of FFF

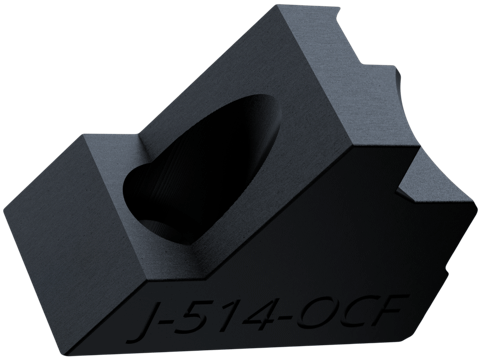

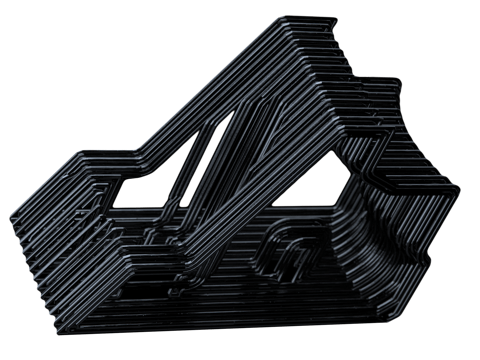

Performance Parts On-Demand

We print composite parts using a continuous fiber reinforcement that provides a better strength-to-weight ratio than machined aluminum.

Industrial Strength Materials

Explore FFF Materials

Below is a list of materials we offer for Fused Filament Fabrication.

ONYX

Onyx is 40% stiffer than ABS and provides the foundation for composite printing. It can be printed on its own or reinforced with any of our continuous fibers.

CARBON FIBER

Carbon Fiber is our stiffest and strongest fiber. It has superior stiffness and minimal deflection, making it strong enough to replace aluminum at half the weight.

FIBERGLASS

Use fiberglass reinforcement to print parts that need to be stronger than our standard plastic materials, such as ABS or HIPS, but at the most affordable price possible.

NYLON

Nylon is a non-abrasive material that can be stiffened with any of our continuous fiber options. It’s a versatile material both with and without fiber reinforcement.

KEVLAR

Kevlar has low density and high durability, which makes it great for applications that involve a lot of motion or require a fixture to interface with production parts.

HSHT FIBERGLASS

With superior heat resistance and similar flex strength to carbon fiber, HSHT fiberglass is ideal for applications requiring high heat, elasticity and impact resistance.