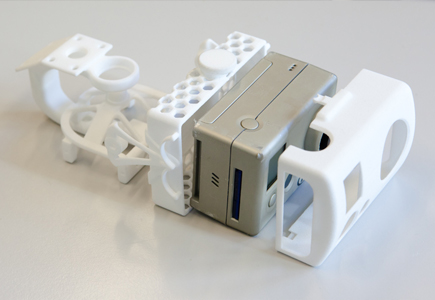

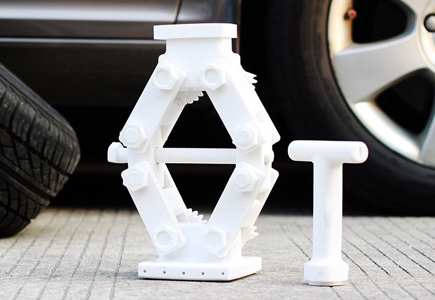

Nylon parts have a smooth white surface that is non-abrasive and easily painted. It’s best suited for non-marring applications that require repeated use and handling. Nylon can be printed on it’s own or reinforced with any of our continuous fibers.

Additive Technology: FFF

Nylon

A non-abrasive, engineering grade thermoplastic. Nylon is extremely versatile on it’s own or it can be strengthened with any of our continuous fiber reinforcements.

Tough Never Looked This Good

Print durable parts with a beautiful surface finish.

Part Resolutions

50 Micron – 0.05 mm

100 Micron – 0.1 mm

125 Micron – 0.125 mm

200 Micron – 0.2 mm

Max Part Size

330 x 270 x 200 mm

( 12.9 x 10.5 x 7.8 in )

Available Colors

Material Tech Specs

Strength

50%Impact Resistance

30%Heat Deflection

40%Surface Quality

70%Strength

70%Impact Resistance

70%Heat Deflection

40%Surface Quality

70%Strength

85%Impact Resistance

80%Heat Deflection

80%Surface Quality

70%Strength

95%Impact Resistance

65%Heat Deflection

40%Surface Quality

70%Strength

87%Impact Resistance

60%Heat Deflection

40%Surface Quality

70%Material Properties

Result

ASTM Test

Tensile Modulus

Tensile Stress at Yield

Tensile Strain at Yield

Tensile Stress at Break

Tensile Strain at Break

Flexural Strength

Flexural Modulus

Heat Deflection Temp

Izod Impact – Notched

1.7 GPa

51 MPa

4.5%

36 MPa

150%

50 MPa

1.4 GPa

105º F

110 J/m

D638

D638

D638

D638

D638

D790

D790

D648 B

D256-10 A

Applications

Functional Prototypes

Mechanical Parts

Assembly Line Fixtures

Replacement Bushings

Inspection Hardware

Jigs, Brackets & Chassis Parts

End-Use Engineering Parts

Housings & Enclosures

Continuous Fiber Reinforcements

Advantages Of Nylon

Non-Abrasive Surface

Our Nylon material is resilient, with a non-abrasive smooth surface. It’s great for applications requiring fatigue and vibration resistance.

Industrial Durability

Nylon is both impact and chemical resistant, with the highest elongation at break. This makes it one of our most durable thermoplastic materials.

Fiber Reinforcement

We can increase the mechanical properties of Nylon parts by adding a continuous fiber reinforcement to strengthen specific infill areas.