Additive Technology: DLP

Digital Light Projection

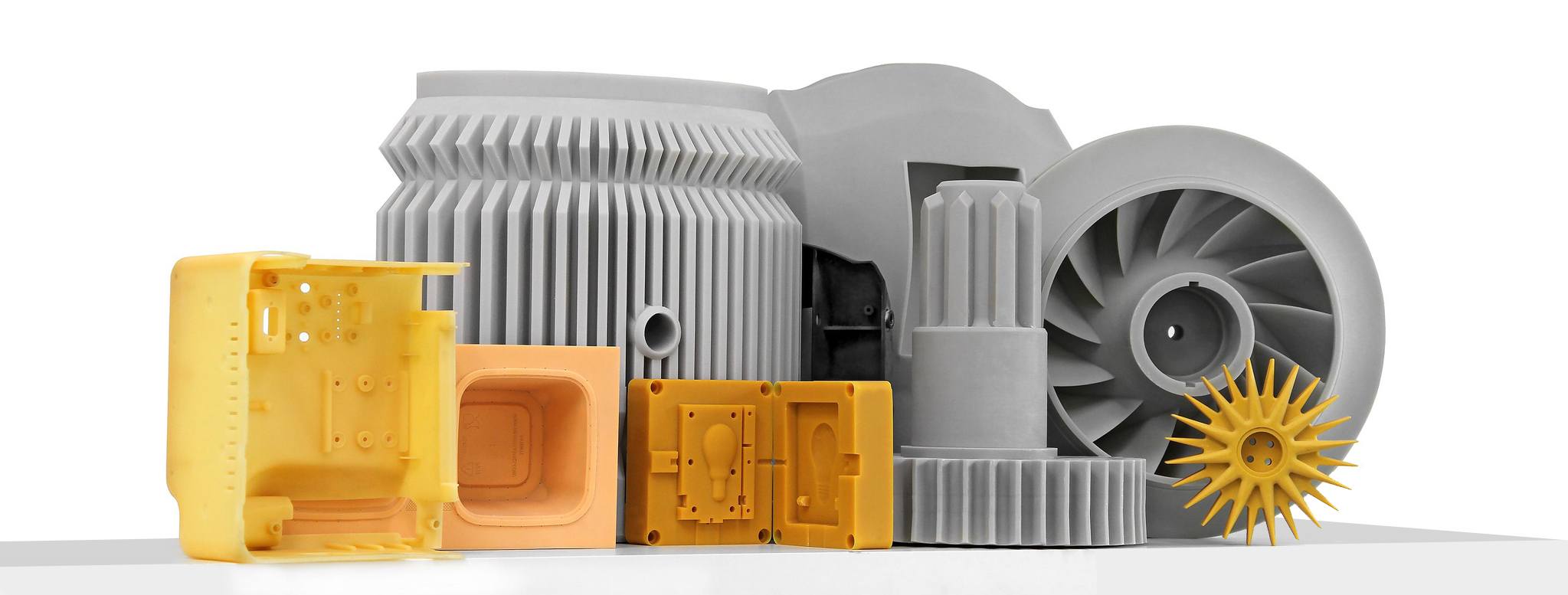

DLP technology allows for a wide variety of materials for end-use part applications.

Description

DLP technology uses a layer-less ultraviolet projector to cure photopolymer resin. It offers a higher resolution than other technologies, which allows you to print parts with fine details and surface finishes.

Strengths

Fine features, with high detail, smooth, injection mold like surfaces and industrial grade materials.

Weaknesses

Support marks may be visible.

Industrial Resins

ABS Tough, RigidForm and Loctite 3840

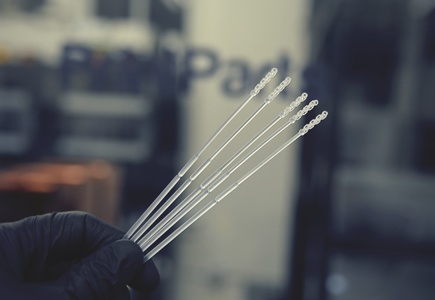

Medical Resins

E-Guide Soft and E-Clear

Price

$$$$$

Lead Time

3-4 Days

Tolerances

± 0.1 mm

Min Wall Thickness

0.5 mm

Max Build Volume

180 x 101 x 175 mm

( 7.09 x 3.98 x 6.9 in )

Resolutions Available

50 Micron – 0.05 mm

100 Micron – 0.1 mm

Advantages of DLP

Industrial Grade Parts

We offer a wide range of materials for end-use applications.

Have questions about Digital Light Projection?

Our additive specialists can help.

Explore DLP Materials

Below is a list of materials we offer for Digital Light Projection.

ABS Tough

ABS Tough is ideal for a wide variety of end-use applications, including snap-fit parts and assembly items which require durability with some elasticity.

E-Guide Soft

E-Guide Soft is a high-performance, biocompatible material that has excellent flexural and tensile strength. It’s ideal for use in a wide variety of impact-resistant medical devices.

Loctite 3840

An acrylic liquid resin great for semi-rigid, general-purpose industrial use applications. It’s great for parts that require fine print resolutions, exceptional surface finish and low shrinkage.

RigidForm

Available in translucent amber, gray and black finishes, RigidForm has a high tensile strength that delivers good heat deflection and water resistance.

E-Clear

E-Clear produces strong, tough, water-resistant parts especially for applications in the custom medical devices, prototyping and end-use parts. It is one of the clearest 3D printing materials currently on the market