Additive Technology: SLS

Selective Laser Sintering

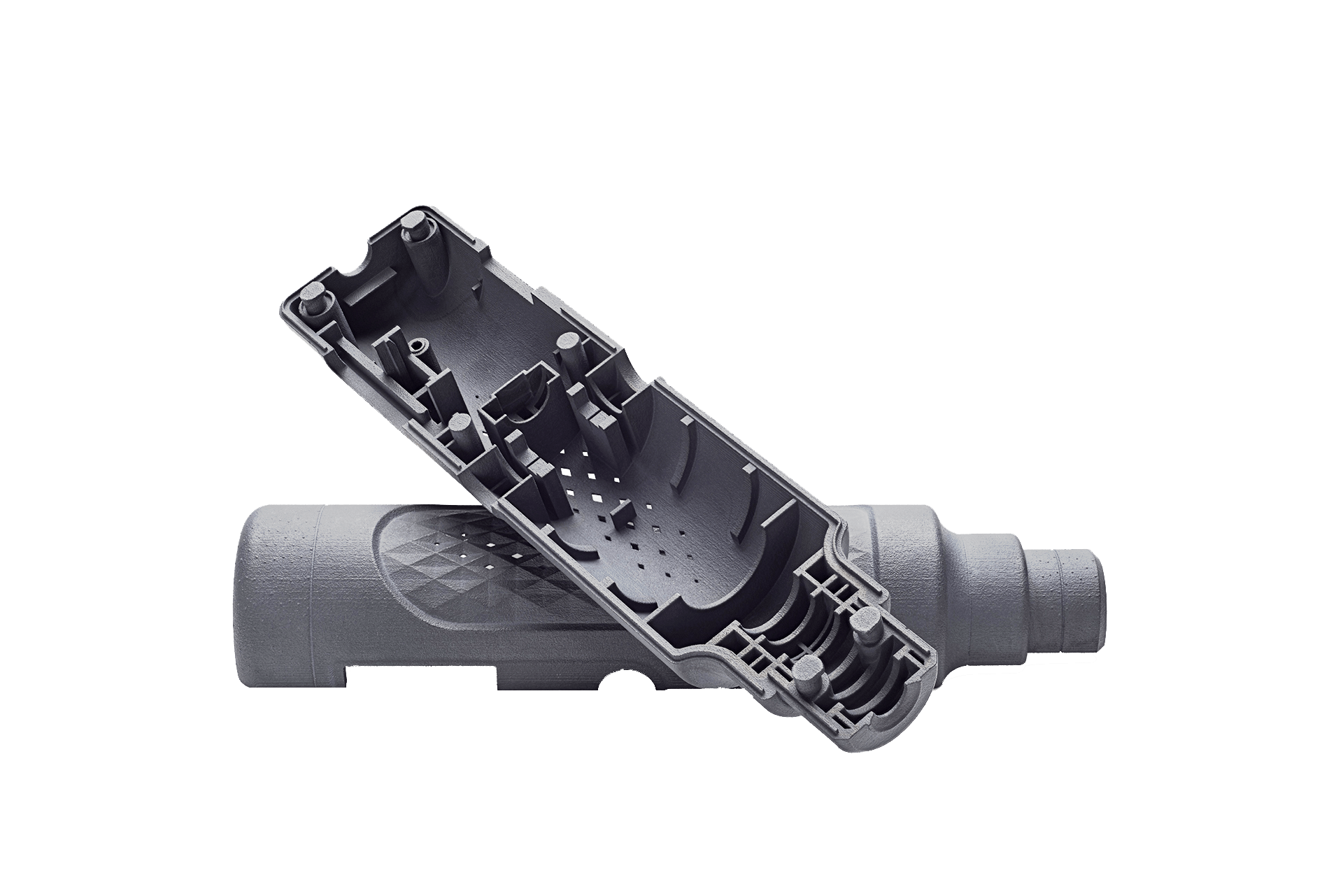

Selective Laser Sintering is a self-supporting powder process that enables a variety of design and print strategies to increase part performance and boost print productivity.

Description

Selective Laser Sintering uses a high-power laser to fuse small particles of plastic powder. The high accuracy and consistency of SLS makes it ideal for high quality production parts.

Strengths

Supportless printing allows for complex geometries, fine features and undercuts. Parts produced with SLS have excellent mechanical characteristics, with strength resembling that of injection-molded parts.

Weakness

Limited colors – Natural Grey or Dyed Black

Base Materials

Nylon 12

Price

$$$$$

Lead Time

3-5 Days

Tolerances

± 0.5 mm

Min Wall Thickness

1.0 mm

Max Build Volume

165 x 165 x 320 mm

( 6.5 x 6.5 x 12.6 in )

Resolutions Available

100 Micron – 0.1 mm

Advantages of SLS

Exceptional Quality

Nylon 12 can be delivered in a natural grey finish or dyed pure black.

Industrial Strength

Explore SLS Materials

Below is a list of materials we offer for Selective Laser Sintering.

Nylon 12 - Natural Grey

Nylon 12 is a highly capable material for both functional prototyping and end-use production of complex assemblies and durable parts.

Nylon 12 - Dyed Black

Fast print speeds, high-density nesting and no support structures allow for maximize use of build volume to print more parts.